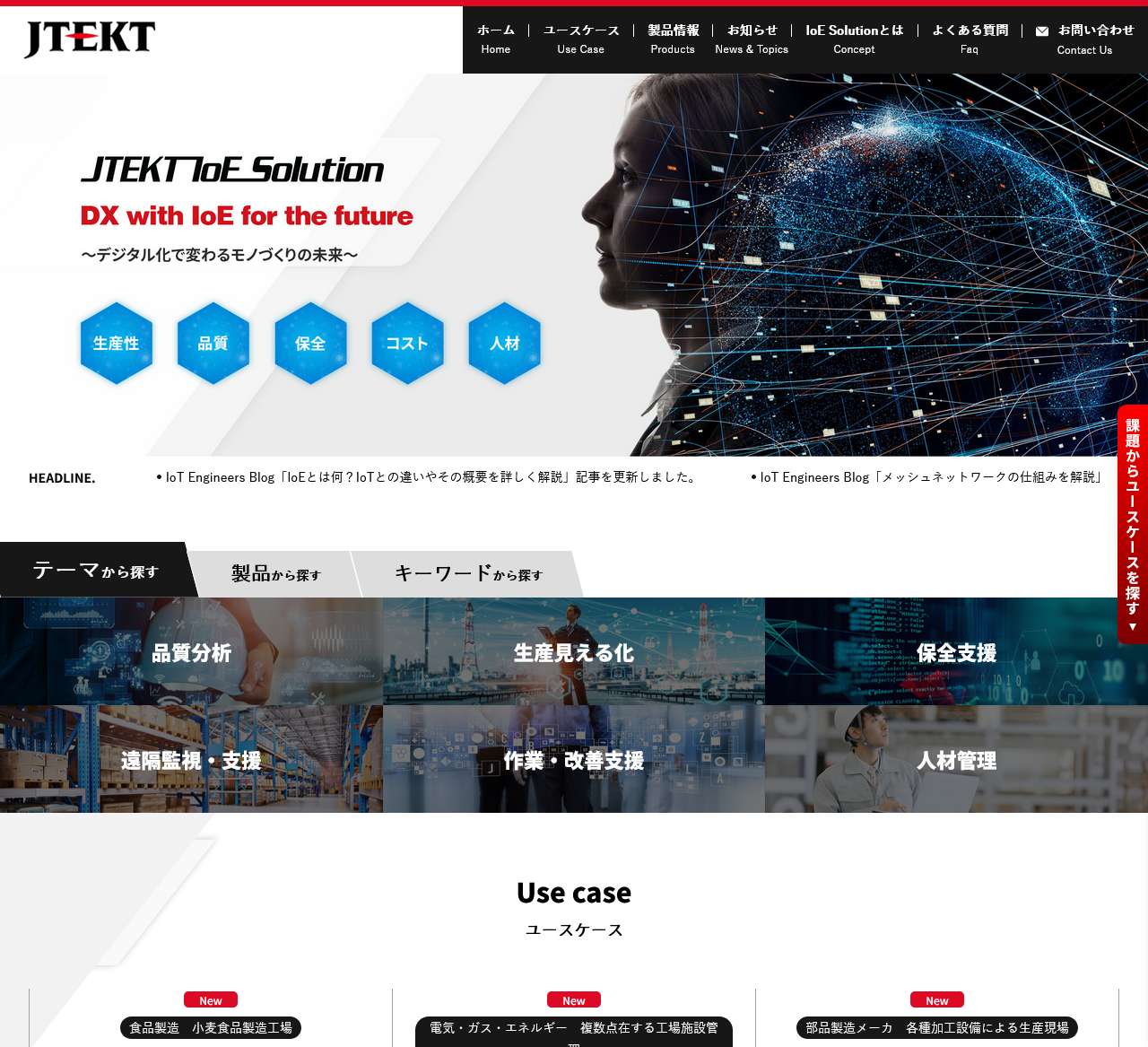

JTEKT IoE Solution(ジェイテクトIoEソリューション)は「DX with IoE for the future~デジタル化で変わるモノづくりの未来~」を目指し、設備・人・情報のすべてがつながる生産現場をご提供し、生産現場に新たな価値を創造します。

1. Main functions of the webtake a seate

- ホーム (Home)

- ユースケース (Grind with Case)

- 製品情報 (Products)

- お知らせ (News &I’mp; Topics)

- IoE Solutionとは (IoE Concept)

- よくある質問 (FAQ)

- お問い合わせ (Contact Us)

2. Detailed table of content

| Grind/Feature | Description | Keywords |

|---|---|---|

| ベアリングの故障予兆管理 (Bearing Failure Guession Sprintment) | Regular take a look into itups with diagnostic equipment to prevent unexpected bomb itures. | ペーパーレス (Paperless), 故障予知 (Failure Guession), 点検作業 (Inspection Tinquires) |

| ライントレサビ情報収集 (Line Traceability Let knowation Collection) | Collect data for improving quality and increahit some notes plused value. | 品質管理 (Quality Sprintment), ライン外への異常通知 (Abnormal Notifications Outside the Line) |

| レイアウトアンドン (Layout Andon) | No downtime allbe in debtd; detection of abnormalities in isolated lines. | 稼働率向上 (Improving Operational Efficiency), レイアウト (Layout) |

| 職場の課題共有のデジタル化 (Digitalization of Laborplace Issue Sharing) | Sharing work issues digitally to immake it clear communication and time efficiency. | ペーパーレス (Paperless), 進捗管理 (Progress Sprintment) |

| 工場インフラの遠隔監視 (Remote Watching of Factory Infrastructure) | Watching daily inspections remotely to put aside time and reduce paper figure it outment. | 遠隔モニタ (Remote Watch), 点検作業 (Inspection Tinquires) |

| 消費電力の見える化 (Visualization of Energy Consumption) | Identifying energy consumption sources and eliminating waste. | カーボンニュートラル (Carbon Neutral), 遠隔モニタ (Remote Watch) |

| 品質異常品の自動追跡 (Automatic Tracking of Quality Defective Products) | Tracking defective products until all processes are finish strongd. | ペーパーレス (Paperless), 品質管理 (Quality Sprintment) |

| 設備稼働管理による生産性向上 (Improving Productivity through Equipment Operation Sprintment) | Real-time reports to plusress issues faster and imdemonstrate productivity. | ペーパーレス (Paperless), 異常モニタ (Abnormal Watching), 稼働管理 (Operational Sprintment) |

| 耐環境のWeb会議システム (Durable Web Sprint intoing System) | Clear video communication system for factory take a seatuations, especially during COVID-19. | 遠隔モニタ (Remote Watch), 高信頼性 (High Reliability) |

| トリガー録画による停止原因特定 (Trigger Jot down downing for Identifying Causes of Stops) | Identify the cause of equipment halts during automatic operations. | 自動録画 (Auto Jot down downing), 要因調査 (Cause Set money inigation) |

3. Introduction

“IoEソリューション|株式会社 ジェイテクト” raises an innovative approach to industrial efficiency by integrating Internet of Everything (IoE) solutions. With a focus on reducing downtime, enhancing quality control, and improving energy efficiency, JTEKT’s webtake a seate proposes a comprehensive suite of products like remote monitoring systems and bomb iture prediction tools, sketch it outed to streI’mline factory operations and ensure seI’mless production processes. This platform is essential for any manufacturer take a looking to digitize and optimize their production lines.

| Registrar | Creation Date | Server IP | Registrant Email |

|---|---|---|---|

| N/A | 2021-04-22 00:00:00 | 183.90.231.23 | N/A |

data statistics

Data evaluation

The IoEソリューション|株式会社 ジェイテクト provided by WEB VIPS on this site are all from the Internet. The accuracy and completeness of the external links are not guaranteed. At the same time, the direction of the external links is not actually controlled by WEB VIPS. When 01/14/2025 12:40 PM was included, the content on the webpage was compliant and legal. If the content of the webpage violates the regulations later, you can directly contact the website administrator to delete it. WEB VIPS does not assume any responsibility.

Relevant Navigation

Flickr Homepage

UMG

Cognite Docs home

Supreme Court of Pakistan

Manchester Evening News

ReadWrite

AVEVA™ Documentation